Impurities in process gas can pose significant challenges in industrial settings, leading to persistent issues such as deposits and caking in critical plant components. These issues can disrupt operations, decrease efficiency, and lead to costly downtime. To maintain optimal plant performance and ensure uninterrupted operations, continuous and effective separation of these impurities is essential.

Tailored Solutions for Effective Impurity Separation

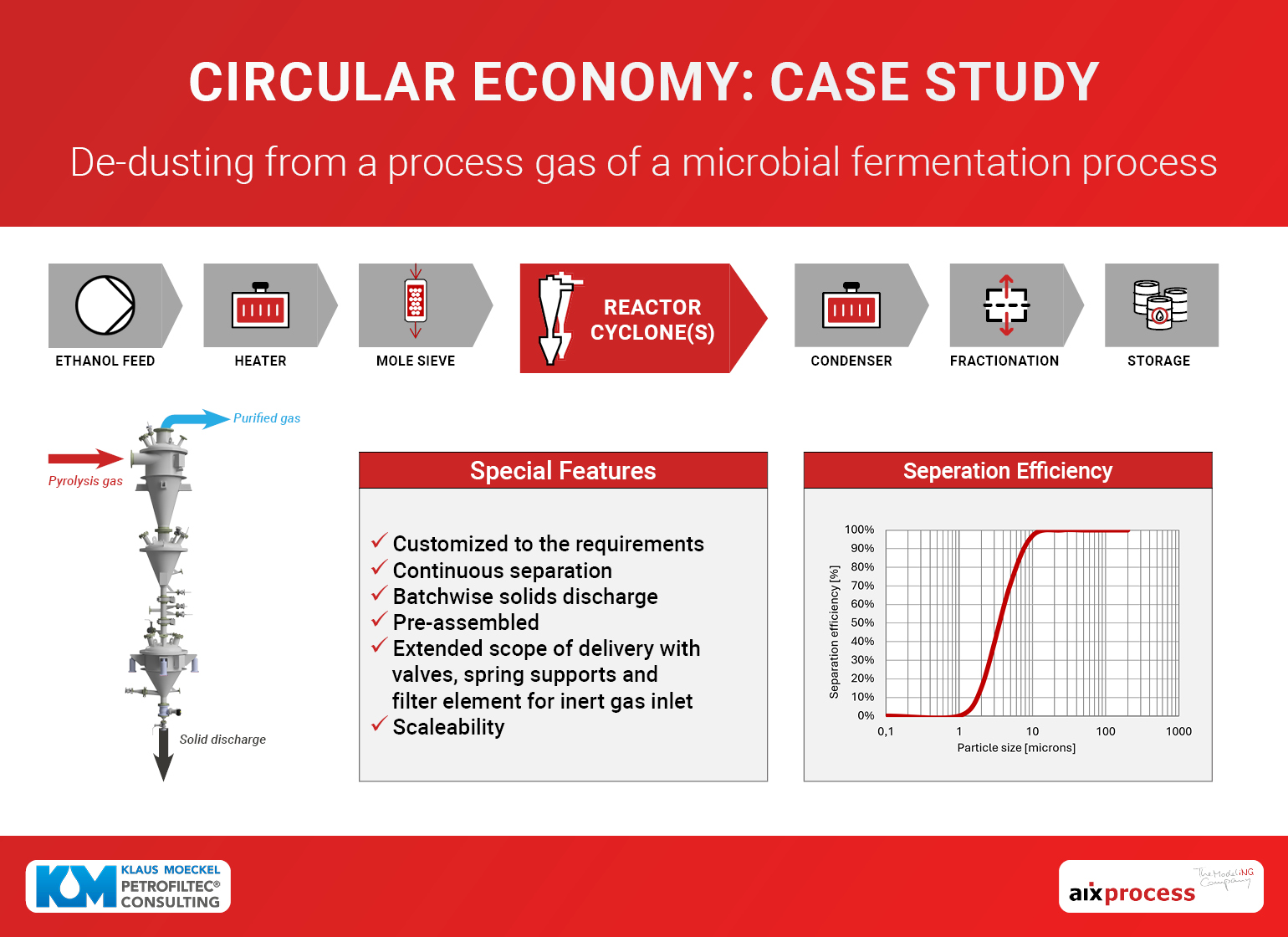

To tackle these challenges, it is crucial to implement a customized, integrated approach that aligns with the unique needs of each plant. At the core of this strategy is a single-stage centrifugal separation unit, meticulously designed to continuously remove solid particles from the gas stream. This advanced apparatus is equipped with heat tracing and insulation to prevent condensation and the hardening of solids, which could otherwise lead to blockages and operational interruptions.

The system also features a discharge lock that can be activated during regular operations, ensuring a seamless, continuous separation process and preventing the accumulation of impurities. This innovative approach not only addresses the immediate issue of impurity buildup but also enhances the overall reliability and efficiency of the plant.

Benefits of Continuous Separation

The continuous and efficient separation of impurities from process gas offers several key benefits, including:

- Improved Process Reliability: By preventing deposits and caking, the risk of unexpected downtime is minimized, ensuring stable operations.

- Enhanced Efficiency: With fewer interruptions and a more streamlined process, overall plant efficiency is significantly improved.

- Extended Equipment Lifespan: Reducing the buildup of impurities minimizes wear and tear on equipment, leading to longer service life and reduced maintenance costs.

- Consistent Product Quality: Maintaining a clean gas stream ensures that the end products meet quality standards consistently.

A Comprehensive Approach is Key

Optimizing plant performance goes beyond simply choosing the right equipment. It requires a deep understanding of the plant's specific needs, designing tailored solutions, and ensuring seamless integration into existing systems. A comprehensive approach that considers all aspects of the process is essential for achieving sustainable and efficient operations.

Learn More

With extensive experience in process optimization and impurity separation, aixprocess provides end-to-end solutions tailored to your specific needs. Whether you're looking to improve operational efficiency, enhance product quality, or extend equipment lifespan, our team of experts is here to help. Contact us today to learn more about how we can support your operation and help you achieve your goals.