As in the chemical industry, thermo-processes are broad in their application as well as product requirements. Asphalt production produces dozens of different qualities, produced in batches requiring a few hours each. At the same time, making a single high quality graphite electrode takes an average of 40 days with a highly accurate cooling-off curve. This is a true challenge when combined with fuel price rallies and a conversion to more sustainable fuels.

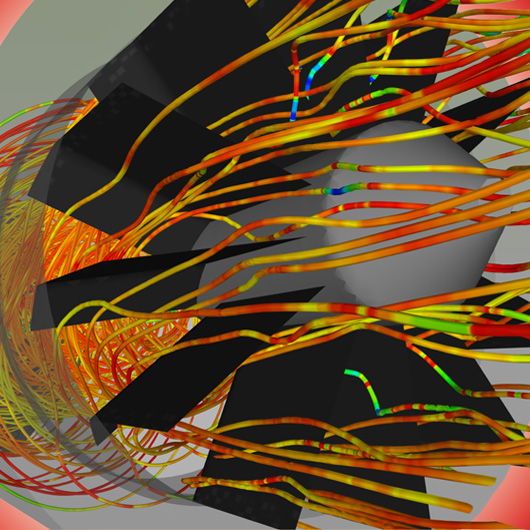

aixprocess' subject matter expertise in high temperature processes is the enabler of efficient energy utilisation. The usage of our CFD digital twins to optimise local phenomena, such as airflow on a burner, helps our customers attain tremendous gains in energy usage, as well as the usage of customised flowsheets to model long-term processes.

To support our customers in thermo process intensive industries, aixprocess has developed unique experience in:

- CFD Digital twins for:

- Aeration tanks & basins

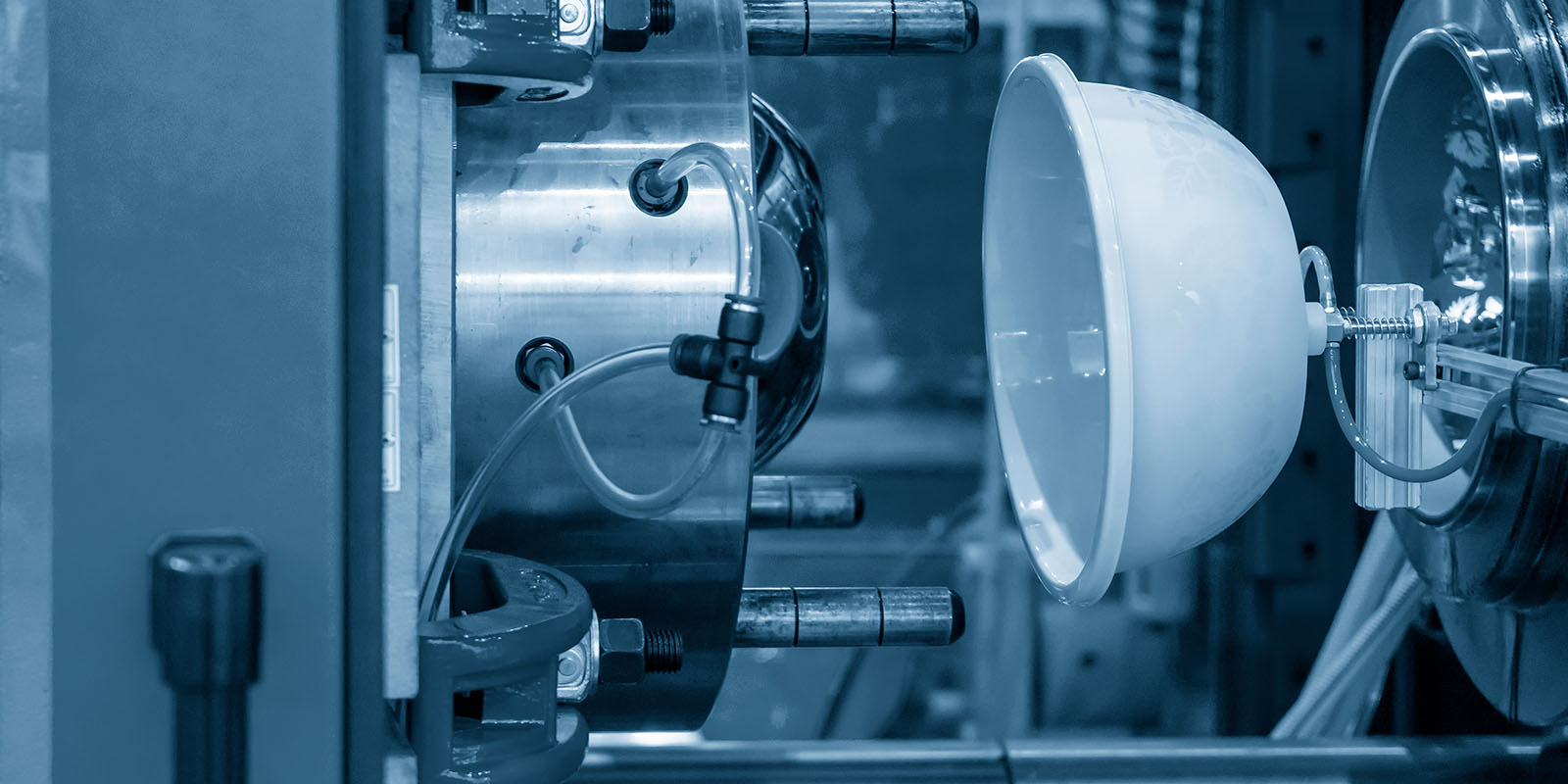

- Burners

- Furnaces

- Airflow & distribution

- Heat exchangers - Tailored process models for long-term operations