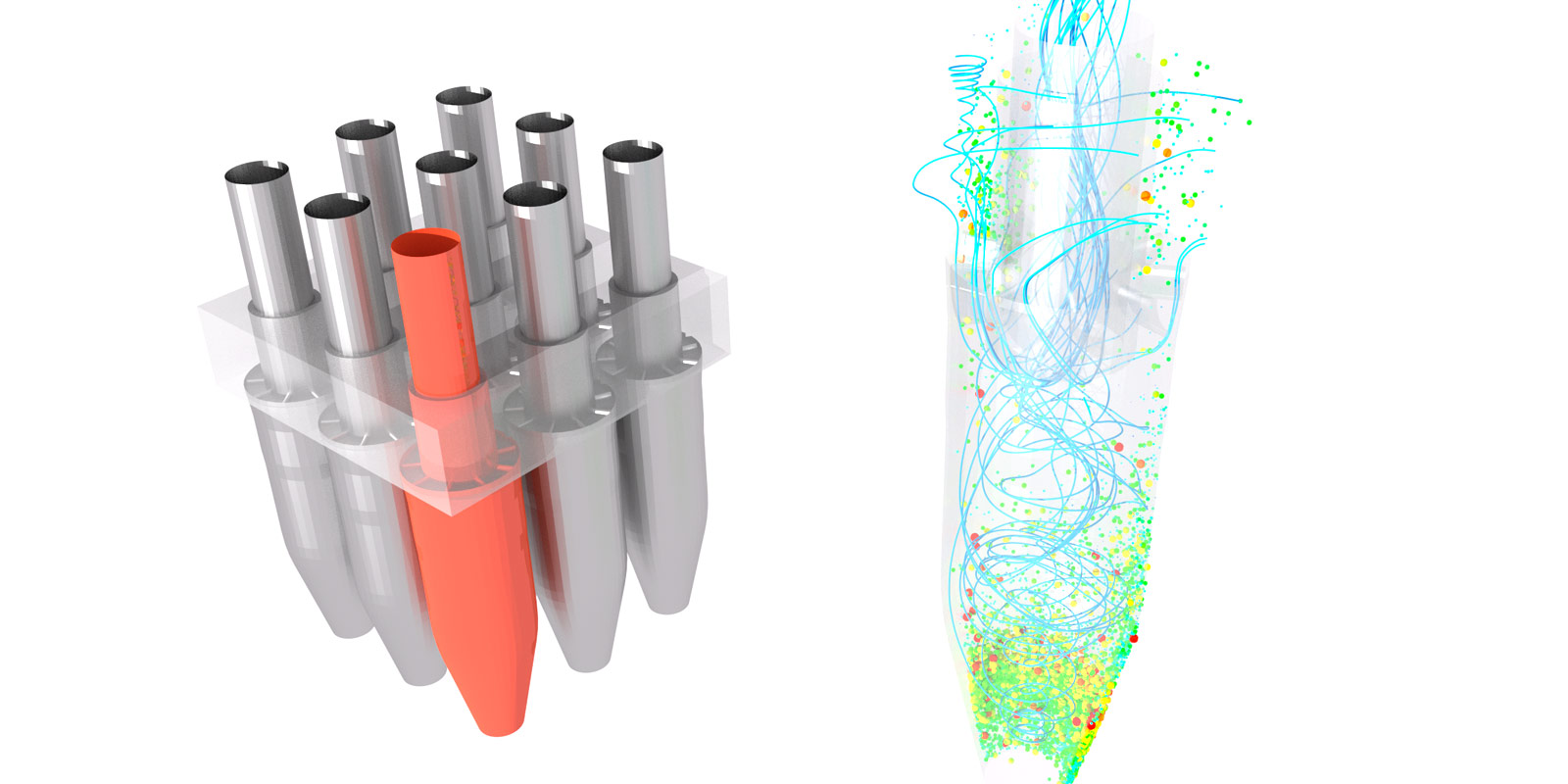

Cyclones & Separators

We Not Only Simulate It - We Build It!

With more than 20 years of experience with 100+ cyclone design and optimisation projects, we are confident in our ability to assume full oversight of the cyclone procurement process. aixprocess is not a classical equipment manufacturer, yet with a network of specialised manufacturers and workshops at our fingertips, we can supply tailored cyclone equipment to meet every need of our customers:

Details

- Gas-solid cyclones

- Hydro cyclones

- Multi-cyclone systems

- Uniflow cyclone for low-pressure drop inline operation

- Swirl separators

- Scrubber and absorber

Selected References

- Vestolit Marl: Design & Delivery Catalyst separating Multicyclone in a fluidised bed reactor installation (2 systems in operation)

- Novelis Lüdenscheid: Design & Delivery foil separation cyclone (in operation)

- SMS Grou Mönchengladbach: Design & delivery of metal powder separation cyclones (in operation)

- Küttner GmbH & Co. KG Essen: Design & Delivery Uniflow Cyclone for pre-Separation of metal dust (cyclone successful in operation)

- Linde AG, Pullach: Basic & Detail Design Decoking Gas Cyclone (cyclone successful in operation)

- Hamon Environmental GmbH, Köln: Basic / Detail Engineering Multicyclone AlOH3 separation (successful in operation)

- Dieffenbacher GmbH, Eppingen: Process design of a new low-pressure drop uniflow cyclone with scrubber option for simultaneous fine particle separation / VOC absorption

scalable product design (multiple systems in operation)