Worldwide competition for potable water increases the pressure on the mining industry to further develop dry beneficiation processes. With the vast amount of raw materials being transported and processed in the mining industry, the potential savings and sustainability growth are enormous.

Where machine utilisation is significant, and mass flow is enormous, the efficacy of digital twins for process design and autonomous operation speaks for itself. Operating a mill with the Mill PILOT real-time optimiser allows for specific energy savings of up to 15%. Remote sites increasingly require autonomous plant operation and remote analysis capabilities. Automated reports keep staff informed regardless of their location, and data collection from remote machines enables monitoring and adaptive control whilst diminishing the need for on-site human resources.

aixprocess has extensive expertise in the following areas:

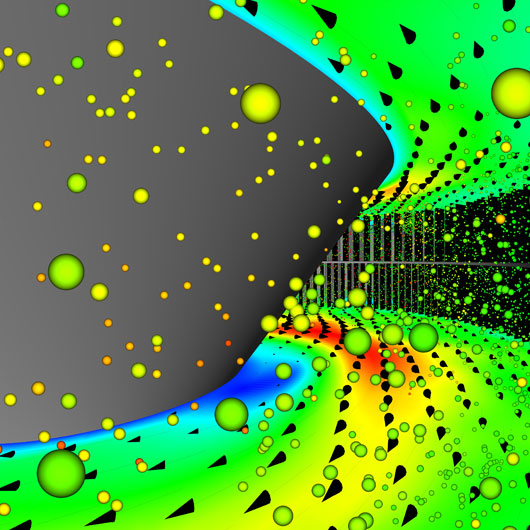

- CFD Digital twins for multi-phase operations

- Mills

- Flotation

- Static & dynamic classifiers

- Pneumatic conveying - Wear minimisation in beneficiation equipment

- Flowsheet tools for beneficiation processes

- Data management platform & Real Time Optimiser