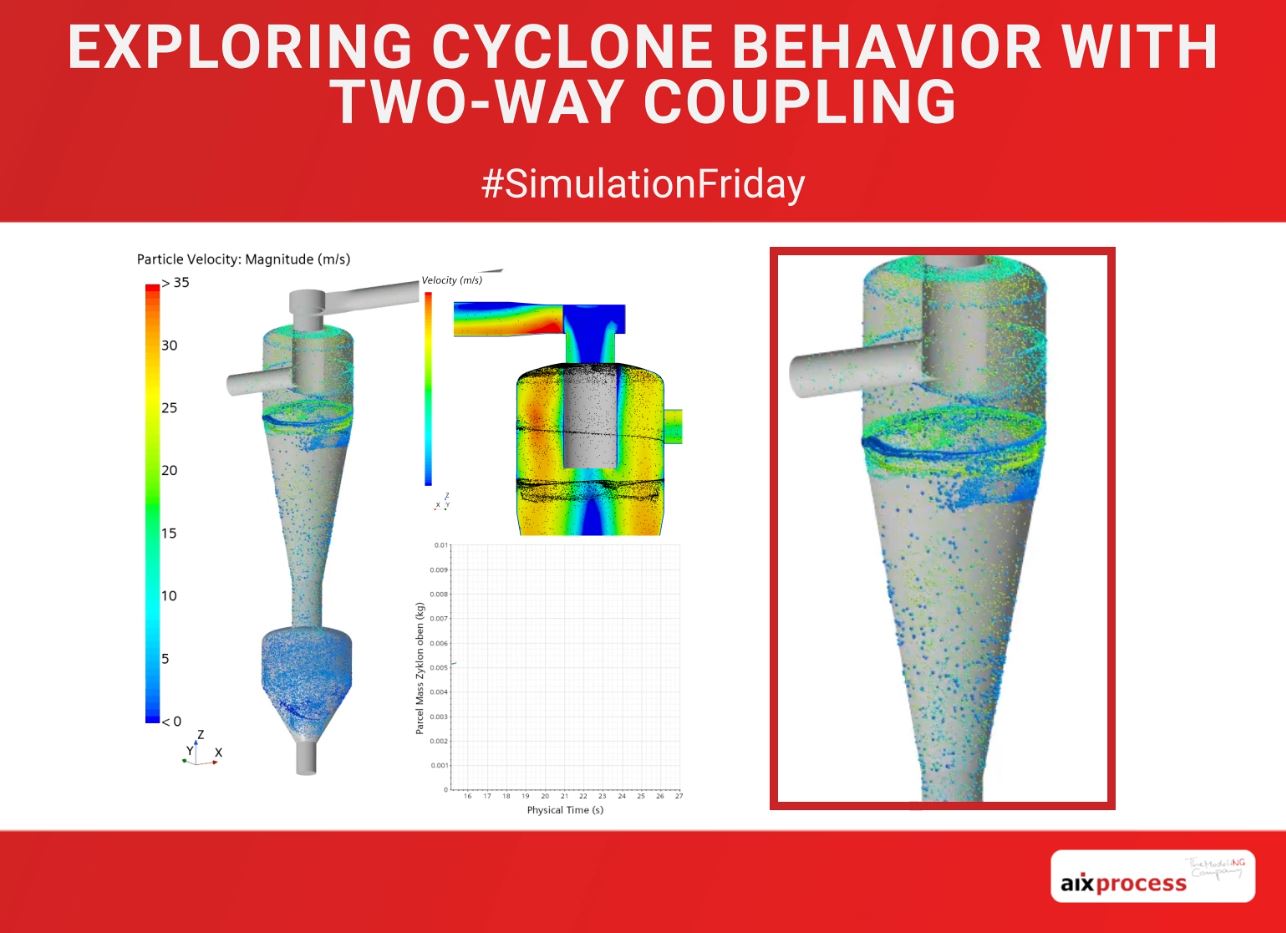

In this #SimulationFriday, we explore the dynamics of industrial gas cyclones using a simulation approach commonly applied to this type of problem. The two-way coupling method considers the interaction between gas and solid phases without including particle-particle interactions, balancing accuracy and computational time when connected with respective cyclone expertise.

Two-Way Coupling in Cyclone Modeling

Practical cyclone experience has shown that solids accumulate under certain geometric and operational conditions, often in ring-like patterns near the cyclone roof or the transition from cylindrical to conical section. As the solids loading in a particular region increases, the flow resistance for the gas is enhanced, causing the gas to flow around these dense solid areas and reducing local gas velocities. When these accumulations reach a critical mass, depending on drag forces from the surrounding gas, a periodic fall-out in solids inventory occurs.

While this phenomenon may not be noticed in standard cyclone applications, this non-stationary behavior leading to a drop in total separation efficiency can be critical from an emission or vibration point of view. It is reassuring to know that CFD reliably depicts such phenomena and thus provides a platform for engineering solutions

Want to solve your challenges in gas-solid applications? Contact us or explore our website to learn more about our customised solutions in cyclone technology using process expertise and CFD.